Other Products & Services

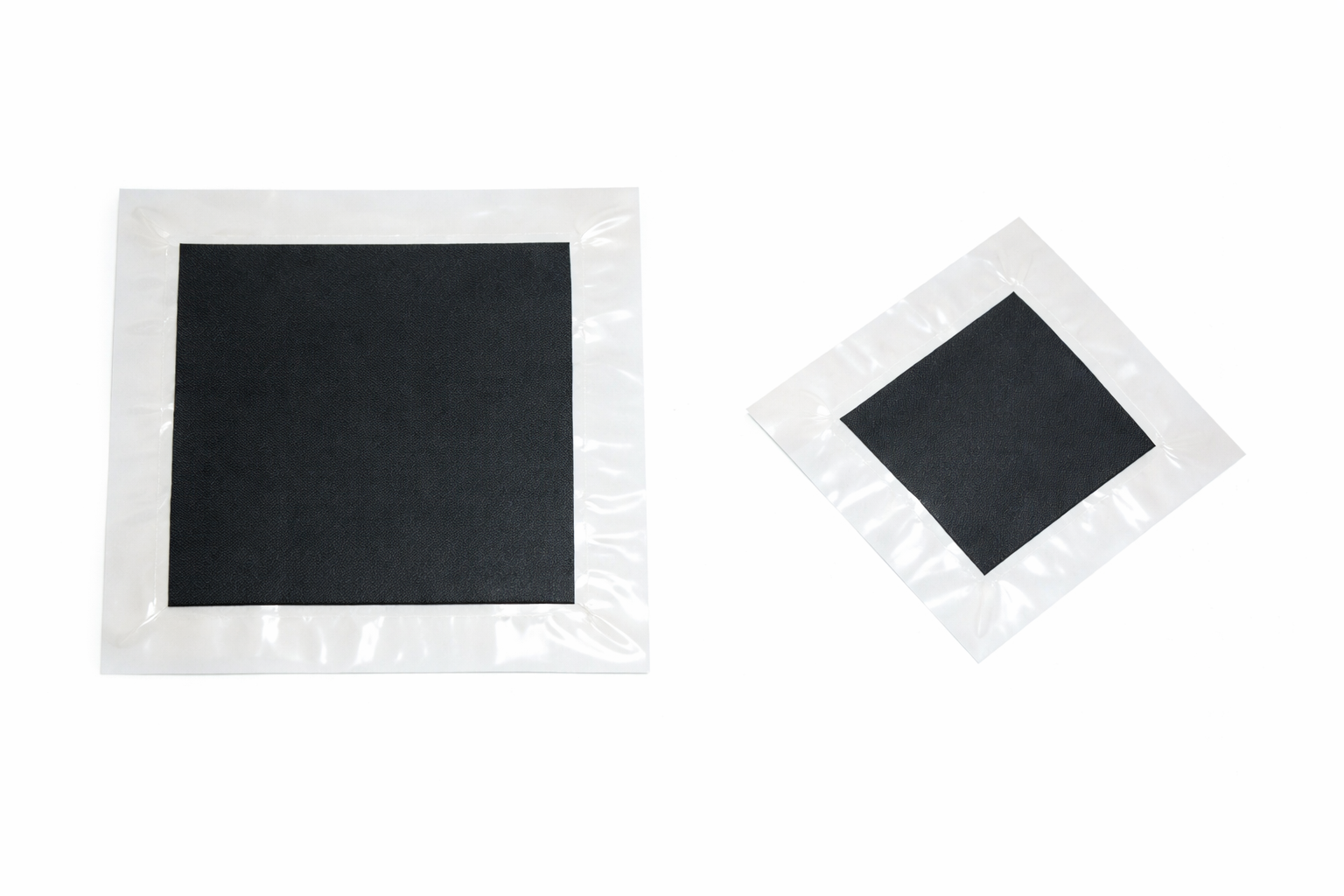

Alkaline Water Electrolyser Separator

Overview

The alkaline electrolyser separator is a critical component that ensures effective gas separation while enabling ionic conduction under harsh alkaline conditions.

Products

AWE Separator (Alkaline Water Electrolyser Separator)

✅ Active area: 100 cm² to 1600 cm²

✅ Large format: Up to 50 × 50 cm

✅ Designed for long-term alkaline stability

✅ Suitable for R&D labs, pilot systems, and commercial stacks

Key Features

✅ High ionic conductivity

✅ Low hydrogen/oxygen gas crossover

✅ Excellent chemical stability in alkaline media

✅ Long operational life

Customization:

Separator dimensions, thickness, and formats can be customized as per cell and stack design.

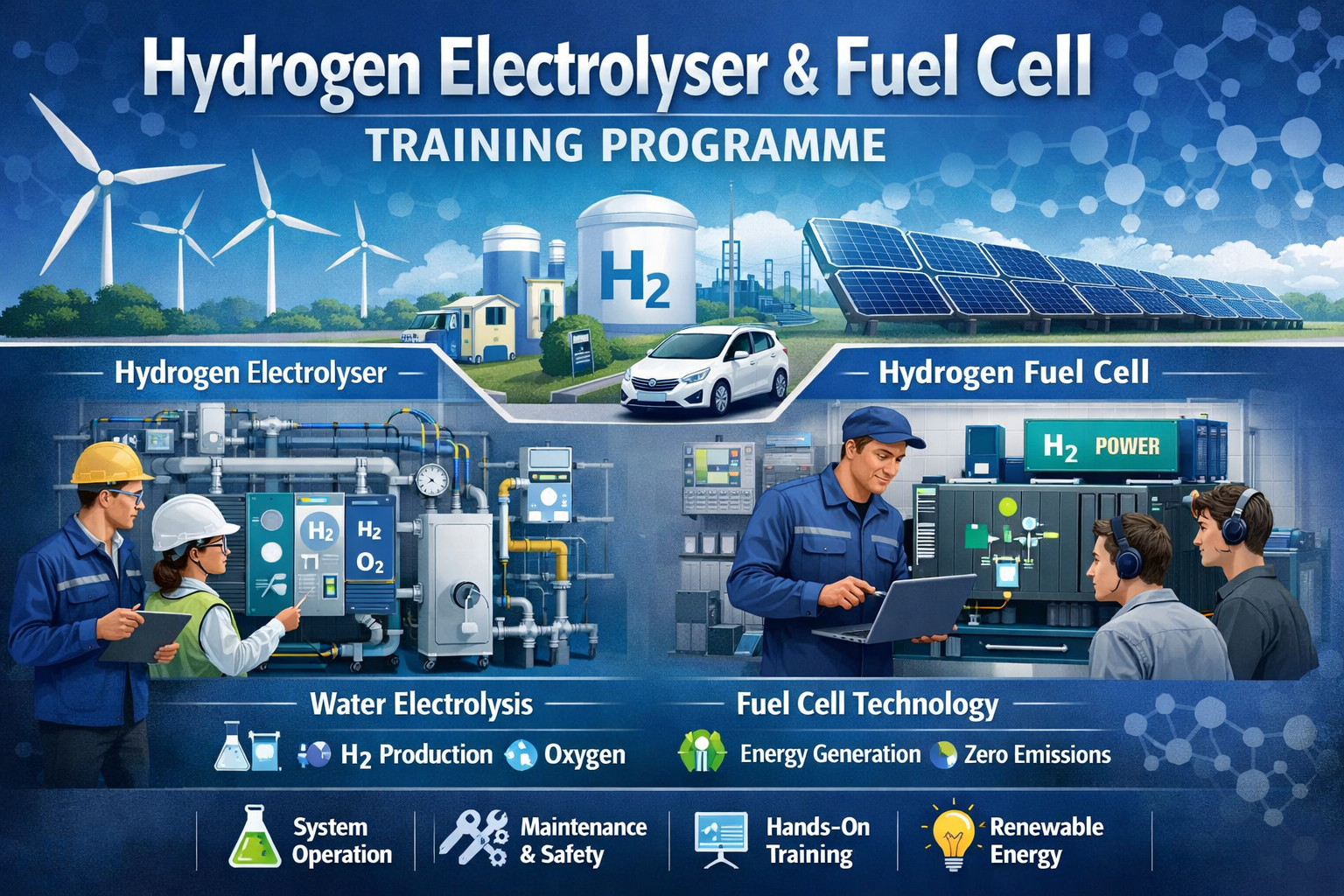

Hydrogen Electrolyser & Fuel Cell Training Programme

Overview

A practical, industry-focused training programme designed to build strong foundational and hands-on skills in hydrogen production, electrolysers, and fuel cell technologies.

Programme Coverage

✅ Hydrogen production, storage, and safety

✅ Electrolysis technologies: PEM, AEM, and Alkaline

✅ Fuel cell fundamentals and real-world applications

✅ Hands-on assembly, testing, and system operation

Key Highlights

✅ Expert-led, application-oriented sessions

✅ Lab-scale demonstrations with working systems

✅ Curriculum aligned with academic, R&D, and industry needs

Ideal For

✅ Engineering students and researchers

✅ Faculty and academic institutions

✅ Clean energy professionals and startups

Customization:

Participants receive the H2Next Certificate, strengthening career prospects in hydrogen and fuel cell technologies.

Fuel Cell Membrane

Product Details

✅ Active area: 100 cm² to 900 cm²

✅ Large format: Up to 30 × 30 cm

✅ PEM fuel cell membranes for research, stack development, and replacement

✅ Custom sizes available for lab and pilot applications

Customization:

Membranes can be supplied in custom thickness, reinforcement, and active area configurations.

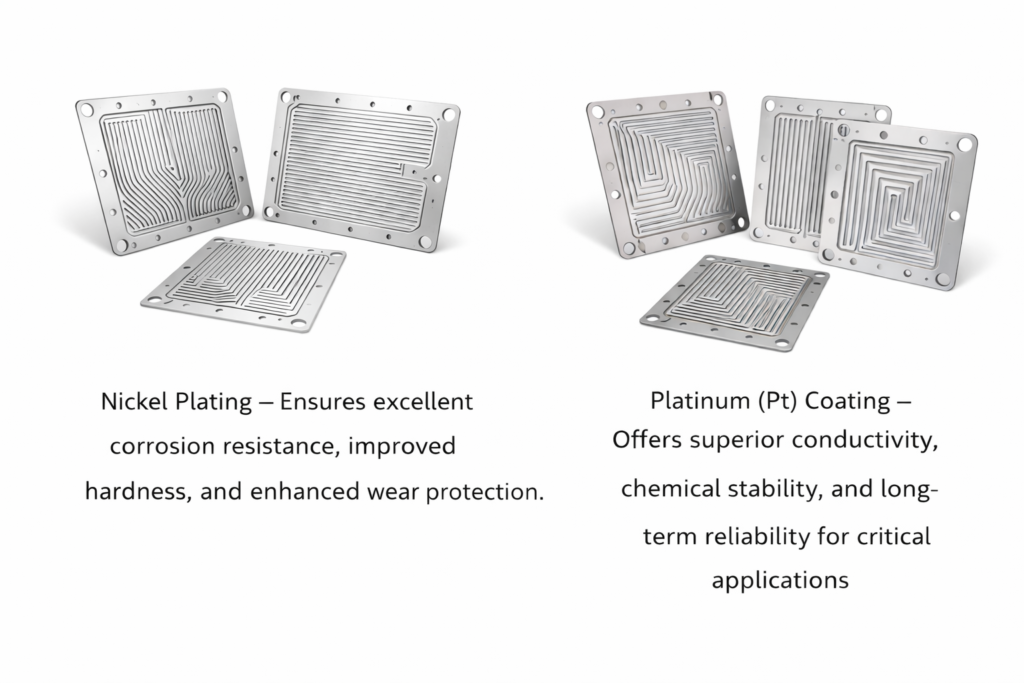

Other Products & Components

Product Details

✅ SS316 / SS316L Electrolyser Plates – Corrosion-resistant mono and bipolar plates

✅ Titanium Grade 5 (Ti-6Al-4V) Electrolyser Plates – For PEM electrolysers (aerospace grade)

✅ Fuel Cell Plates (Mono/Bipolar) – Precision-machined SS316 or Titanium

✅ Nickel Foam – High surface area porous nickel (>99% purity)

✅ Nickel Mesh / Expanded Nickel – Durable conductive structures (>99% purity)

✅ Titanium Porous Plates / Ti Felt – High purity (>99.5%) for PEM anodes

✅ Nickel Plating – Ensures excellent corrosion resistance, improved hardness, and enhanced wear protection.

✅ Platinum (Pt) Coating – Offers superior conductivity, chemical stability, and long-term reliability for critical applications.

✅ Custom Porous Metal Structures – Tailored nickel, titanium, or SS components

✅ Catalyst Coated Electrodes (CCE/CCM) – PEM, AEM, and alkaline systems using >99.9% purity catalysts

Product Images

Customization:

All components can be customized as per customer drawings, material specifications, and application requirements.